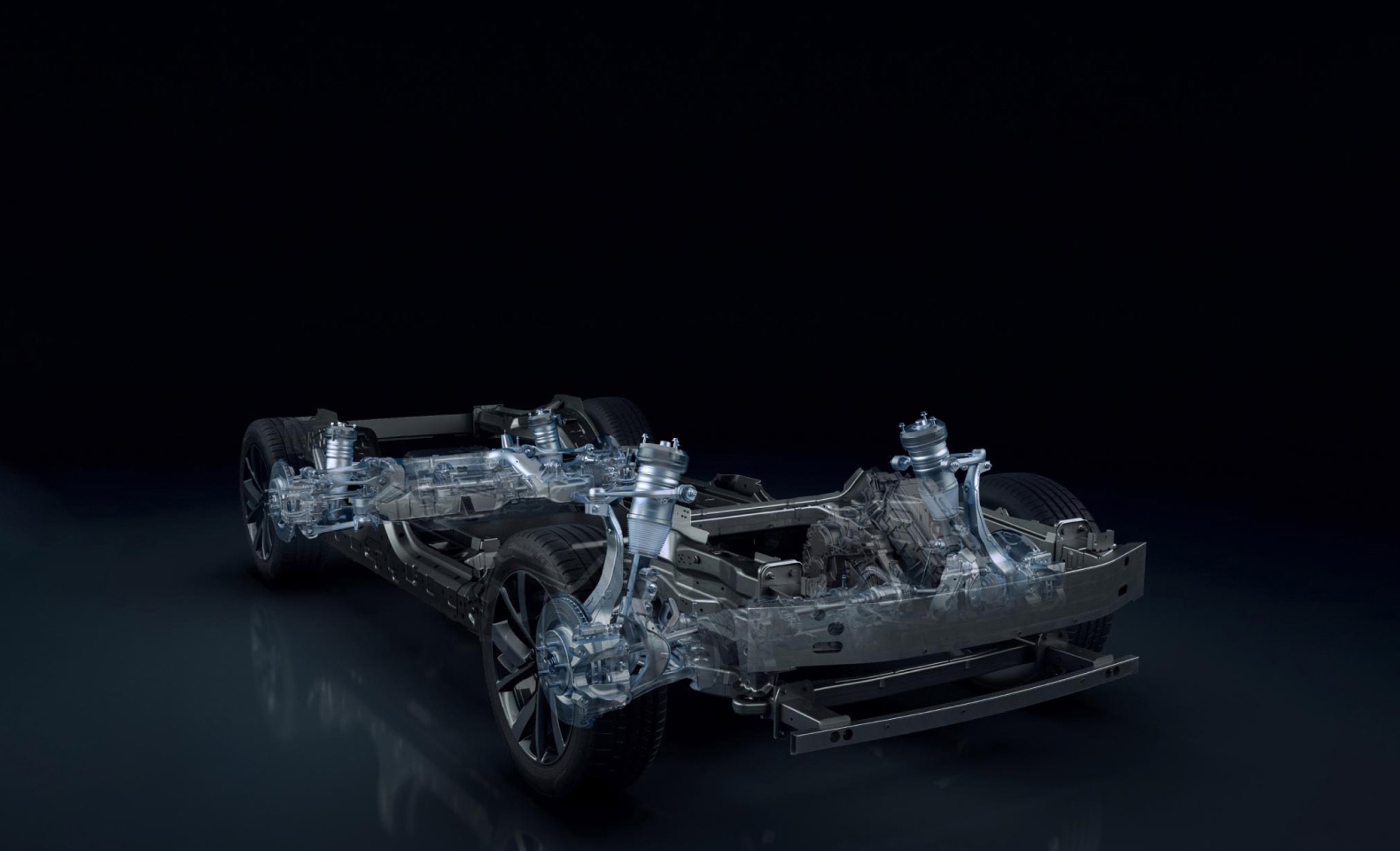

Fortress Safe Body

Keep Every Family Member Safe

Reliability proven through 90+ crash test items, surpassing C-IASI and C-NCAP standards. Safety solutions have been developed and tested for each seat for comprehensive protection.

Front-row

Second-row

Third-row

Li Auto's autonomous driving perception algorithm is optimized for common collision scenarios to help the vehicle more effectively brake and avoid dangers, protecting your family members.

Lane Assist

Vehicle-to-vehicle AEB

Pedestrian and cyclist AEB

The Li Auto L series achieved a score of over 76% in C-IASI pedestrian protection tests , surpassing the 70% benchmark for excellence set by C-IASI

Self-developed

Li Auto Fortress Safe Body™ Technologies

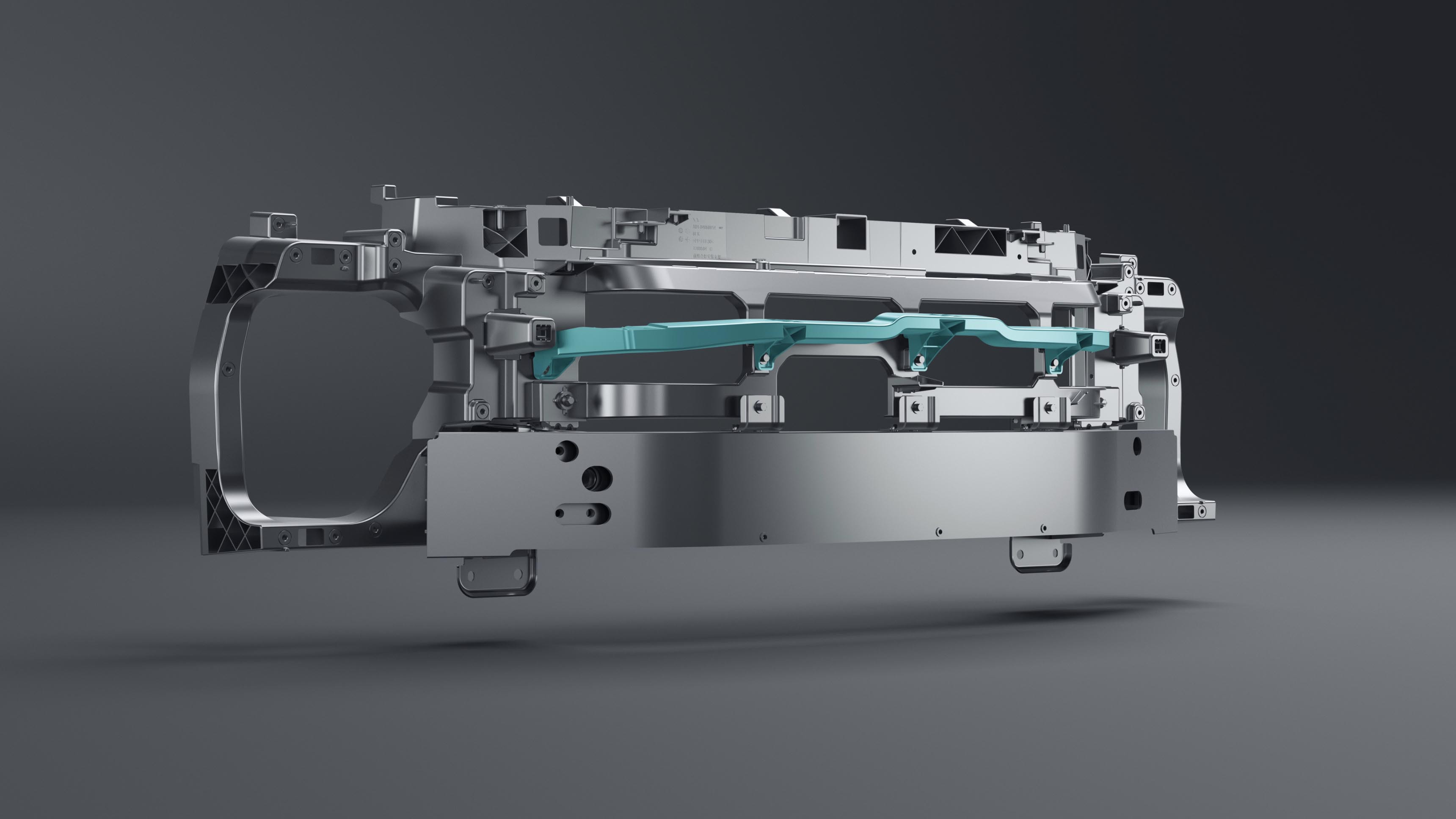

High Standards

Manufacturing

No Flames

Battery Safety

Safety

High C-IASI Ratings